Oral Delivery of Biologics

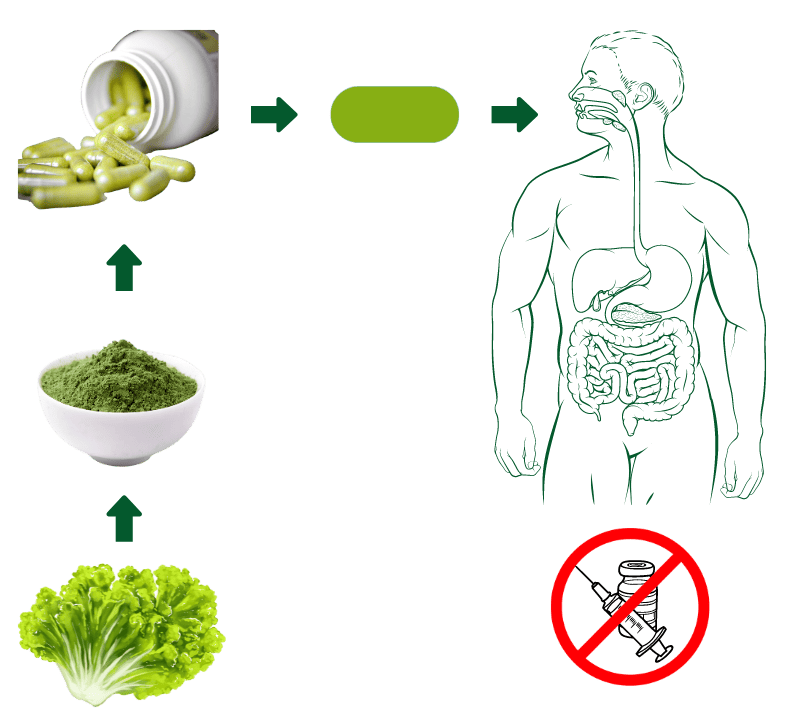

Issues with state of the art peptide production and delivery:

- Difficult to synthesize, decreasing scale and increasing cost

- Must be injected to have an effect due to degradation in the stomach

- Not shelf stable under normal conditions

What we are creating to solve these problems is common food species that are genetically engineered to contain new peptides of our own design that are “bio-encapsulated” by the cell walls of the food species we have engineered. Our first target leveraging this new product platform are novel peptides that interact with incretins to reduce appetite as part of a weight loss plan.

Disrupting Fermentation Processes

Production of desirable proteins usually takes place in cells from mammals, yeast, or bacteria grown and cultivated in a process referred to as precision fermentation. These fermenters require large upfront investment and running costs, have poor scalability, and run the risk of contamination with human pathogens. Using conventional agricultural crop species for protein production, or molecular farming, offers the advantages of lower upfront and running costs, massive scalability, and safety from transmission of human pathogens.

BioDrive’s Platform

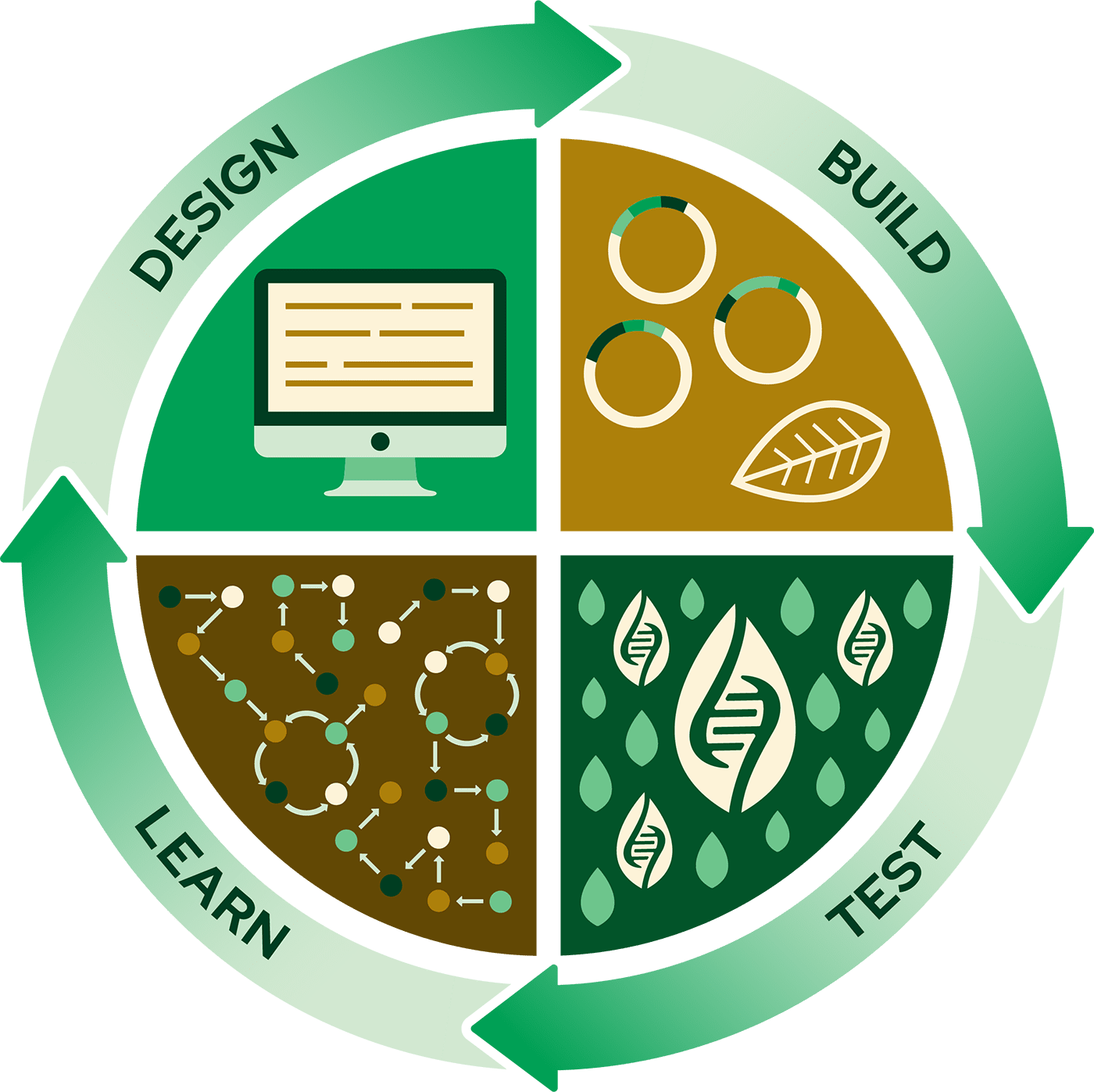

We are developing new approaches to genome editing in agricultural crops to increase yield of transgenic proteins, increase transformation efficiency, and enable effective oral delivery of our engineered proteins. The outcome is a streamlined and cost efficient design-build-test cycle tailored for scalable biology based product development.